The Roots Group of Companies an Indian multinational, with presence in varied Industries like Automotive Components, Mechanised Cleaning, Precision Equipment, Incampus electric vehicles, Cast Components etc..

We have consistently delivered high-quality products and services over the the years and have won the trust and confidence of customers across India and Global markets.

Roots Industries India Limited is the flagship company of the Roots Group and its products find pride of place in some of the world’s most respected automobile brands such as BMW, Harley Davidson, Ducati, Renault Nissan, Hyster Yale, Navistar, PACCAR, CAT, Toyota, VW group etc.,

Our State of Art Manufacturing Facilities are certified with IATF16949:2016, ESD S20.20:2014, ISO14001:2015, ISO45001:2018, EN9100:2018, ISO13485:2016 standards.

The company manufactures a wide range of Electric horns, Electronic horns with multi-functional capabilities, Backup Alarm, DC-DC converters USB chargers and customized Electronic products.

The other divisions of Roots Industries India Limited are High Precision Engineering (Medical, Aerospace, Automobile, Textile, Aluminium, Steel Products, Plastic Machined Parts), Metrology (Calibration Services), Furniture (Ergonomic, Airport Trolley), Electric Vehicles (In campus Vehicles).

We enhance our capability to provide world-class Electronics Manufacturing Services (EMS) with personalized support. We specialize in component procurement, high mix/low to high volume contract assembly. Offering both turnkey and board-level assembly, we excel at working closely with customers to meet unique assembly and testing requirements.

Why EMS with Roots?

Roots Group Capabilities to provide variety of services that may include engineering Design, Planning, Procurement, Production, SS/Aluminum fabrication, Subassembly Manufacturing, Turnkey Manufacturing, Variants of Tests covering – FT, ICT, EOL, Burn in Test, Shock & Vibration, Thermal Cycling, Visual Inspection, 3D Automated Optical Inspection, 5D Solder Paste Inspection & Late Stage Customization.

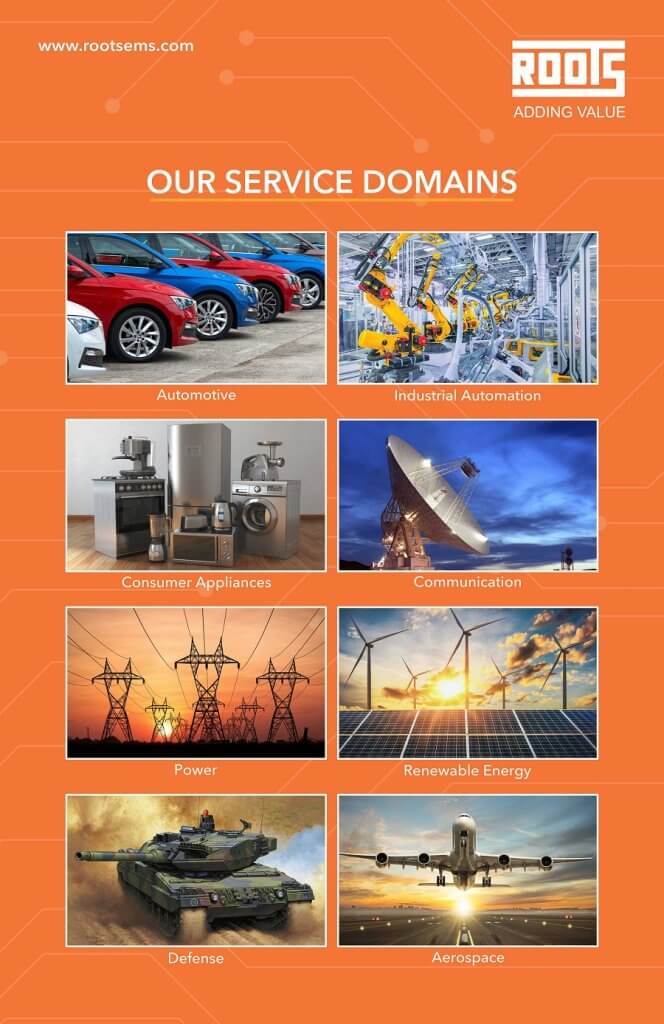

If any value addition requirement for company owned requirements which can manufactured & produced at one roof contact from any sector specific which covers Automotive, Industrial Automation, Consumer Appliances, Communications, Power, Renewable Energy, Defense & Aerospace.

Roots EMS Capabilities Includes:

- SMT Fine Pitch Assembly

- Reflow Soldering

- Pin in Paste Technologies

- Through Hole Soldering

- 1% less than void of Soldering features through Vapor Phase Soldering

- 3D AOI

- 5d SPI

- OE Assemblies

- Box Build Assemblies

- Supply Chain Management

- Plastic Molding

- Metal Stamping

- Project management

- Quality control

- ESD Norms Packaging

Our broad electronics manufacturing expertise comes together to provide complete system build services for simple. “ONE STOP SOLUTION”