PCB Design and Engineering

1

+

Years of Leadership

1

+

Exclusive PCB Design Engineers

1

+

PCB Layout Jobs

1

+

FootPrint Library

1

*6

Support Available

1

%

Customer Retention

CAE Softwares

ALTIUM, FAB 3000, PRO, AUTOCAD, SOLID WORKS, SMIULATION PACKAGES FOR 2D/3D MODELINGS & E DRAWINGS

Our PCB Designing Services

- Schematic capture

- Layout

- Fabrication

- Testing

Our PCB Designers can help you with the following

- Single-sided PCB Design

- Double-sided PCB Design

- Multi-layer PCB Design

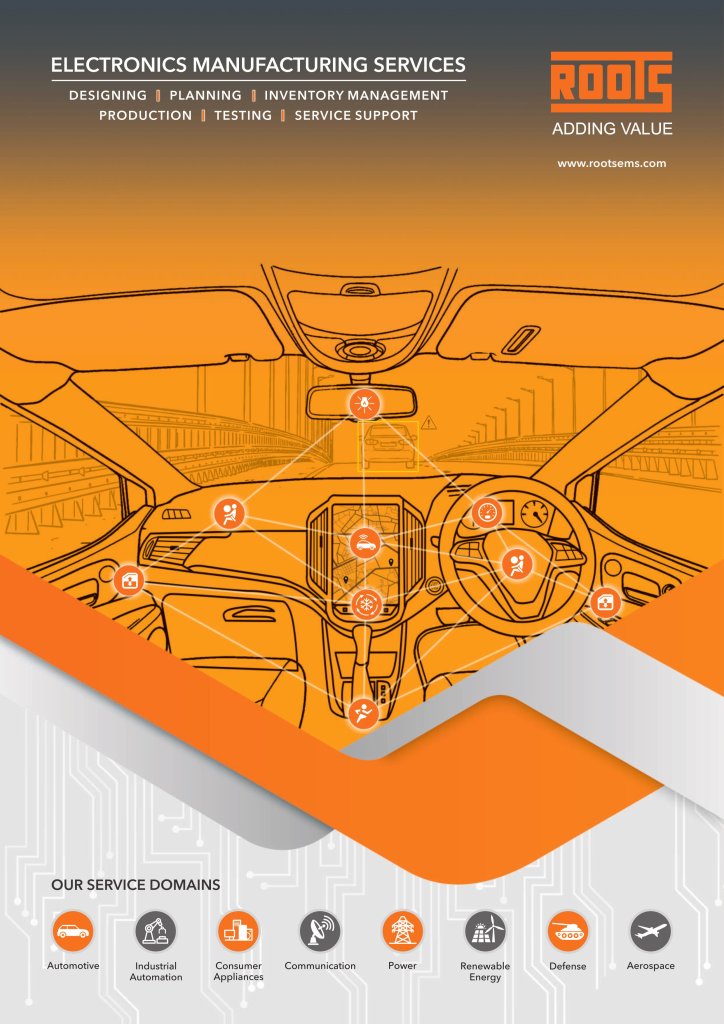

END TO END SOLUTIONS

- PCB Design and Engineering

- PCB Fabrications

- Rapid Prototyping

- New Product Introduction

- PCB Assembly

- Box Build Assembly

- Test & Burn-in

- Supply Chain & Logistics

PCB Design and Layout Process

Our PCB layout services proceed through the following steps.

- Schematic Capturing: Schematic capturing is the first stage involved in the PCB layout design development. Circuit designs are drawn on paper and processed using the schematic editor in a computer. We utilize various types of the schematic capture software for schematic capturing. After the completion of the schematic capture process, a complete electronic design is stored in the file, which is converted into a netlist file. The file features interconnectivity information about component pins or circuit nodes present in the electronic circuit.

- PCB Component Footprint Creation: Component footprint creation helps determine the space available for component placement. A suitable mounting scheme is decided on the basis of component footprint creation. Our PCB designers use Surface-mount technology (SMT) or Through-hole Technology (THT) to place components on the circuit board. The footprint creation helps determine the number of layers, which are needed on the board. We can provide PCBs from a single layer up to 48 layers.

- PCB Routing: This is the next stage after the component placement on the circuit board. Our layout designers utilize a PCB software to route the physical connections between all the components present on the board. The software makes use of netlist derived from the schematic to route physical connections. Our vast experience and expertise enable us to incorporate simulations and complex routing in the PCBs.

- PCB Verification & Analysis: This is an important step in any PCB manufacturing process. Our PCB layout designer ensures the assembly is free from any kinds of defects. We offer a comprehensive range of testing and inspection services. Below given are our services.

Can Roots EMS assist with design for manufacturability (DFM)?

Yes, we offer DFM support tailored to specific project requirements.

What design tools and software do you use for PCB layout and schematics?

We utilize industry-standard tools like Altium 2020 and FAB 3000 for accurate PCB layouts and schematics.

Do you provide multi-layer PCB design services?

Yes, our team is proficient in designing complex multi-layer PCBs.

How do you ensure design accuracy and signal integrity in complex circuits?

We conduct thorough design validation and analysis to maintain signal integrity and design precision.

What is the typical turnaround time for PCB design projects?

Our standard turnaround time for PCB design projects is 6 to 8 weeks.

Do you provide prototype design services?

Yes, we offer prototype design services based on the scope and requirements of the project.