X-Ray Inspection for PCB Assembly

Detecting Hidden Defects

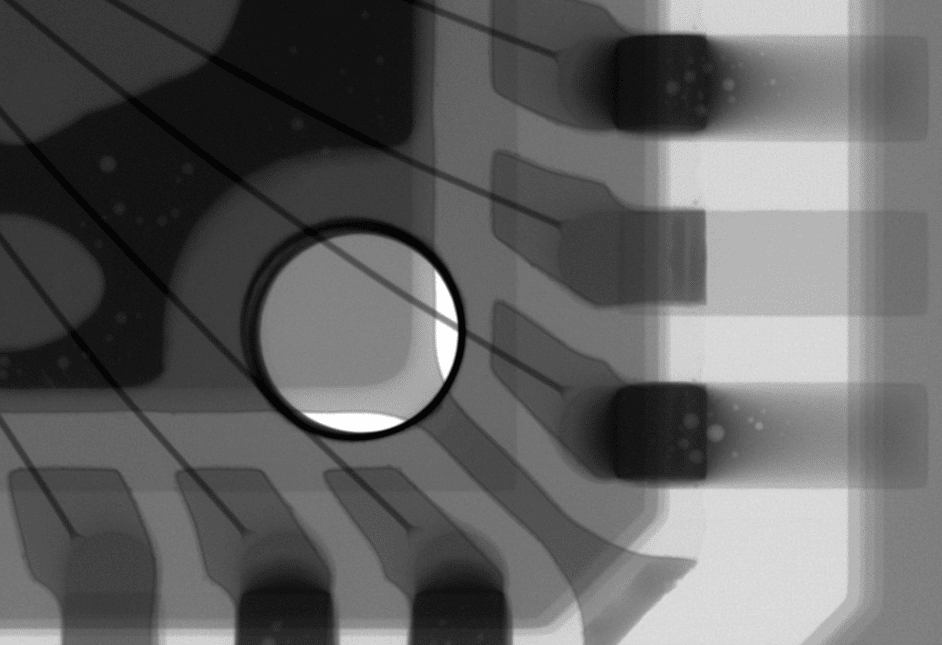

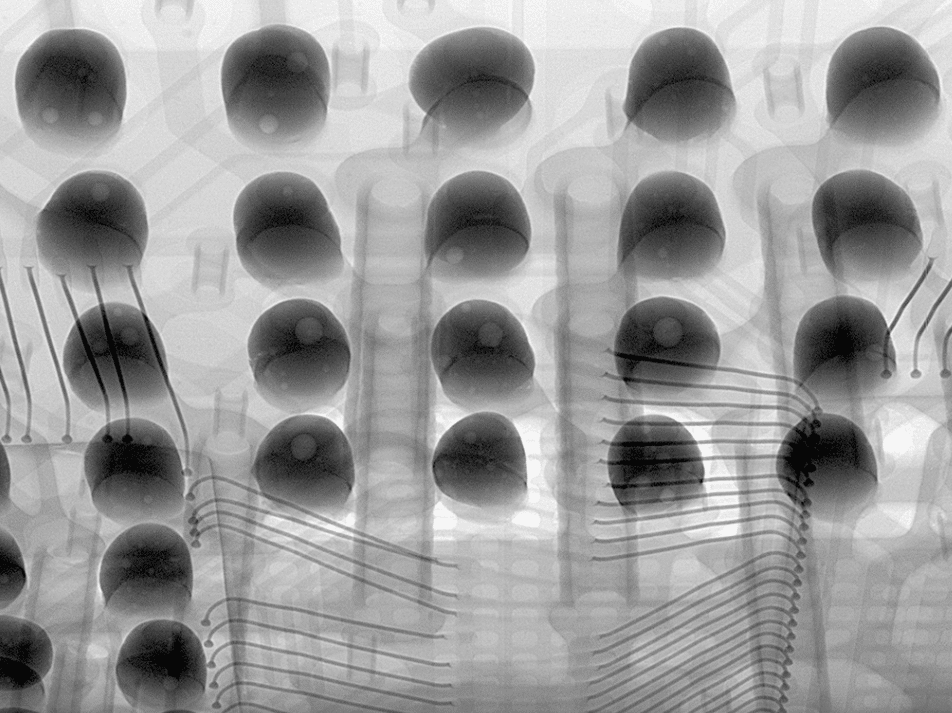

PCB assemblies often involve components like ball grid arrays (BGAs), chip-scale packages (CSPs), and other solder joints hidden beneath the surface. These components can develop:

- Voids in solder joints

- Cold soldering

- Bridging and open connections

Traditional inspection tools cannot see beneath layers of the PCB. X-ray inspection allows manufacturers to view these critical areas without dismantling the board, ensuring every component functions as intended.

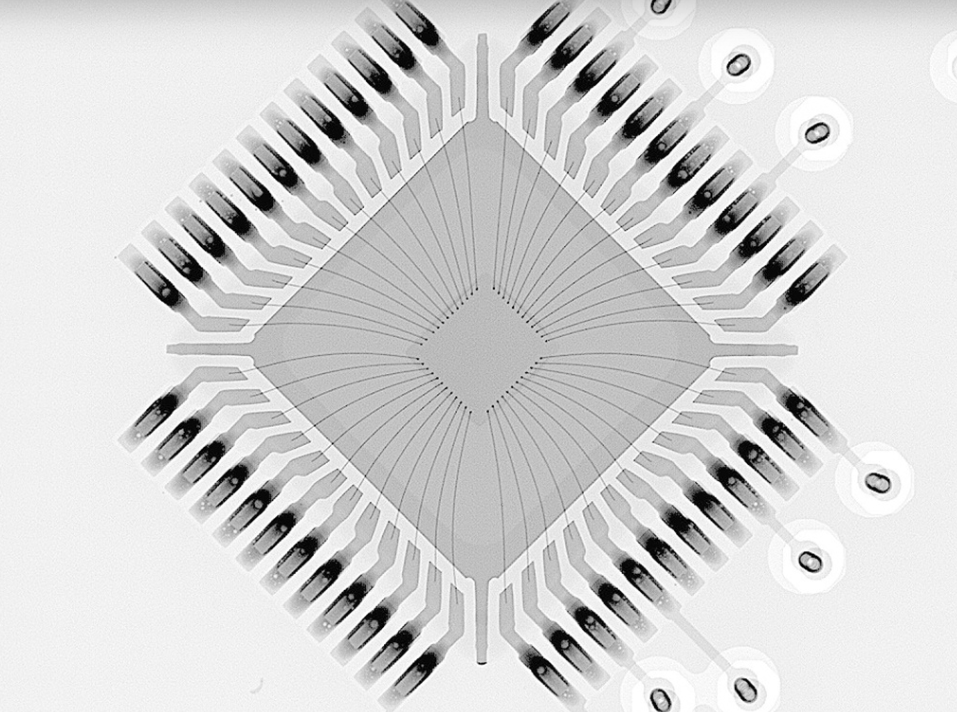

Ensuring Quality in Miniaturized Designs

Modern electronics demand smaller, more complex PCBs, resulting in denser component placement and multi-layered designs. This miniaturization increases the risk of undetectable issues, such as misaligned vias or internal short circuits. X-ray inspection excels in examining multi-layer PCBs for precise alignment and identifying potential failures early in production.

Enhancing Production Yield

Early detection of defects minimizes costly rework or scrap in the later stages of production. X-ray inspection provides comprehensive data for root-cause analysis, helping manufacturers improve processes and prevent recurring issues.

Meeting Industry Standards

Industries like automotive, aerospace, and medical electronics demand uncompromising reliability and adherence to strict quality standards. X-ray inspection ensures compliance with IPC standards and other regulatory requirements by offering unparalleled accuracy in defect detection.

Inspection Capabilities

Components: Electronic components and SMT components (BGA, μBGA, flip chips, and assembled circuit boards)

Solder joints: Visible and concealed solder joints

Defects/defect features: Air inclusions/blow holes in the solder joint (voids), presence, offset, too much/insufficient solder, solder bridge, solder balls, solder sputter (optional), soldering defects, non-wetting, contamination, damaged component, missing or incorrect component, imperfect shape, tombstoning, lifted lead, billboarding, supine, twist, polarity error, wick-up effect (optional), head-in-pillow (balls), THT fill level and pin height

Expertise and Precision:

Our skilled technicians have the expertise to handle complex electronics integration projects. We employ precise assembly techniques to ensure accurate component placement, secure mounting, and proper connectivity.

Quality Assurance:

We have a rigorous quality control process in place. We conduct thorough inspections and testing to verify the integrity, functionality, and reliability of the assembled product, ensuring it meets or exceeds industry standards.

Collaborative Partnership:

We believe in making collaborative partnerships with our clients. Our team works closely with you throughout the assembly process, ensuring effective communication, project understanding, and alignment with your expectations.

Want to explore more? Discover our other services

- PCB design services

- Surface Mount Technology (SMT) services

- Vapor Phase Soldering Services