Vapor Phase soldering

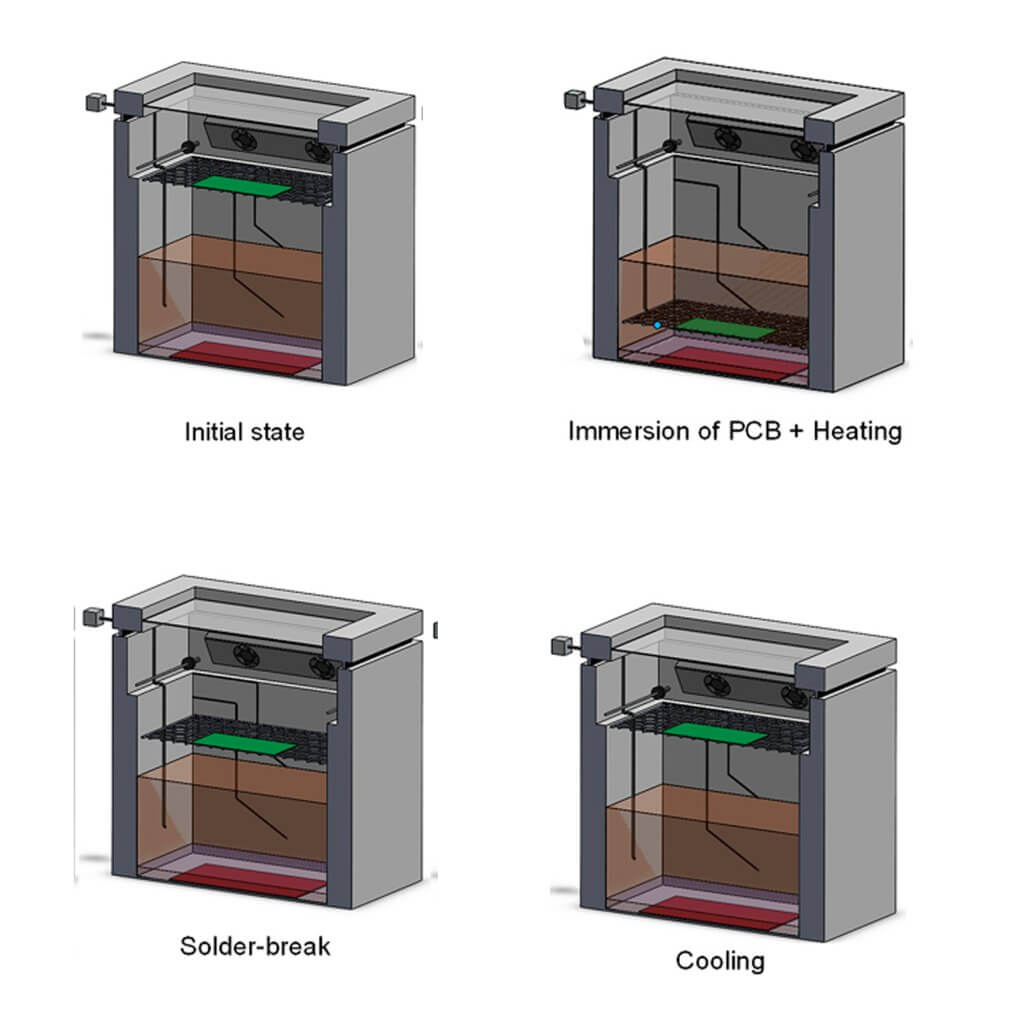

- Multifunctional soldering process zone for Oxidation-free preheating and soldering of assemblies

- Sensor based profiling allows real-time measurement of each soldering process on product level and the automatic creation and controlling of the solder profile

- Cooling zone with convection cooling,Soldering process- and cooling zone separated by automatic locks; Permanent Filtration System (PFS) – pump-less filtration system for continuous filtration of the process medium during the system operation

- Void-less soldering – when solder joints need to have particularly low void rates, it is achievable with a vacuum treatment. The system is equipped with an innovative MULTI VACUUM function.

Vacuum module with multi vacuum process for multiple vacuum treatment of assemblies during soldering. The vacuum zone is installed directly above the soldering zone (clean vacuum technology). The vacuum parameters as throughput (of vacuum pump), end pressure and the speed of the evacuation are freely adjustable. Programmable, fast reacting heating keep the product on soldering temperature

The multivacuum process also enables void-free solder joints where products with an above average outgassing potential are concerned (e.g. high number of layers in multilayer, large processors).

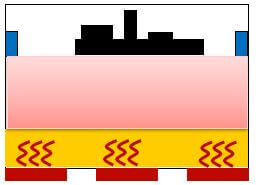

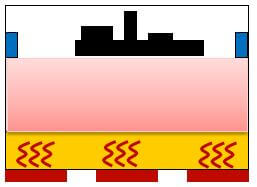

Vapor phase soldering – The procedure

- Process liquid is heated up to its boiling point (e.g. 230C for lead-free applications)

- Boiling point is equal to the process temperature

- Energy supply generates vapor

- Vapor zone builds up and is permanently controlled by sensors

- Vapor temperature is equal to the boiling temperature of the process liquid

- Soldering process can start

- Assembly enters the vapor zone

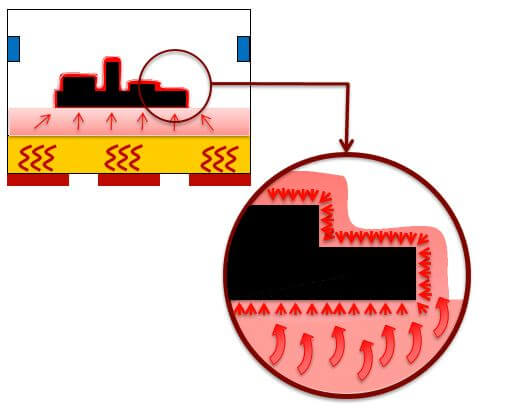

- Vapor condenses on the assembly and creates a closed liquid film around the complete assembly.

- Vapor zone stabilizes on the top of the assembly

- Liquid film excludes oxidation completely

- Through the liquid film, the energy is transferred on the assembly

- The energy transmission is controlled through the vapor creation and therefore with condensation

- With this controlled energy transmission/condensation, the adjusted soldering profile is reached

- Assembly is heating up to vapor temperature

- condensation stops automatically and vapor zone increases again

- Soldering process is finished

- Assembly leaves the vapor zone

- Process liquid evaporates completely

- Dry assembly moves to the cooling zone

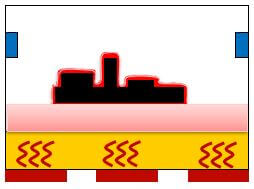

Vapor Phase Soldering

The controlled energy supply regulates

- The produced vapor volume and therefore

- The volume of the condensing process liquid and therefore

The transferred quantity of heat

Result: The Adjusted Soldering Profile

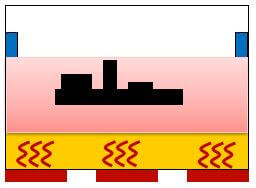

Vapor Phase Soldering with vacuum

Less than 1% void free Soldering

Field of Application

- Soldering of power modules

- High frequency applications

- Mil and space applications

- Products with a very long time or safety requirements

- Voidless soldering of mechanical structures etc

- Operating conditions under high temperature/vibration etc.

APPLICATION IMAGES: