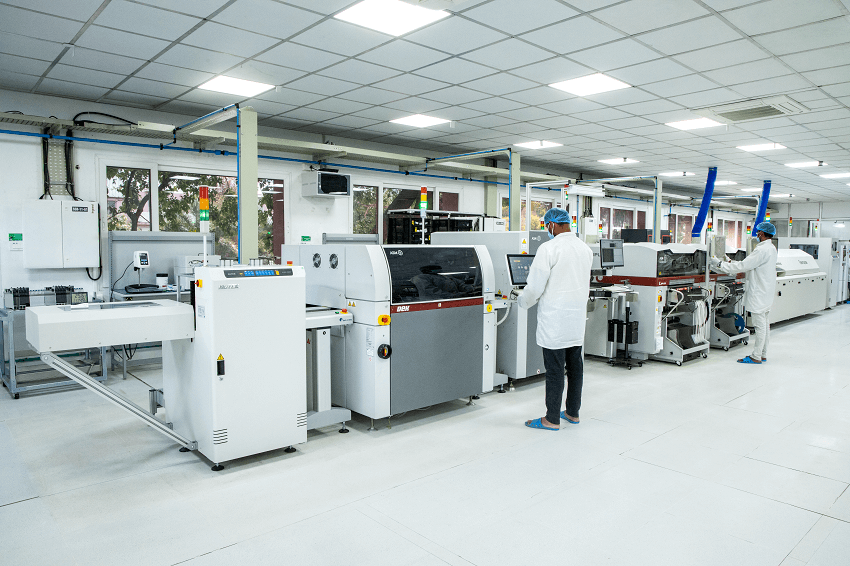

PCB ASSEMBLY & SMT

Advance Technology

We have over 50+ years of immersive experience in manufacturing products like Automotive Horns/Auto Electricals/Mechatronics and our new advanced PCB Assembly technology, resulting in proven processes and a range of services. We provide highly complex PCB assemblies with very high yields. Roots PCB assembly facilities are future-ready, providing support on next-generation chip mounting capabilities. Our Zero-defect approach combined with our state-of-the-art test and inspection system ensures that only high-quality products leave our factories, to be delivered to our various global customers.

CAPABILITIES

- High complex double-sided PCB assembly

- High mix, medium volume assemblies

- Fine Pitch SMT, Through-hole and Box Build Assemblies

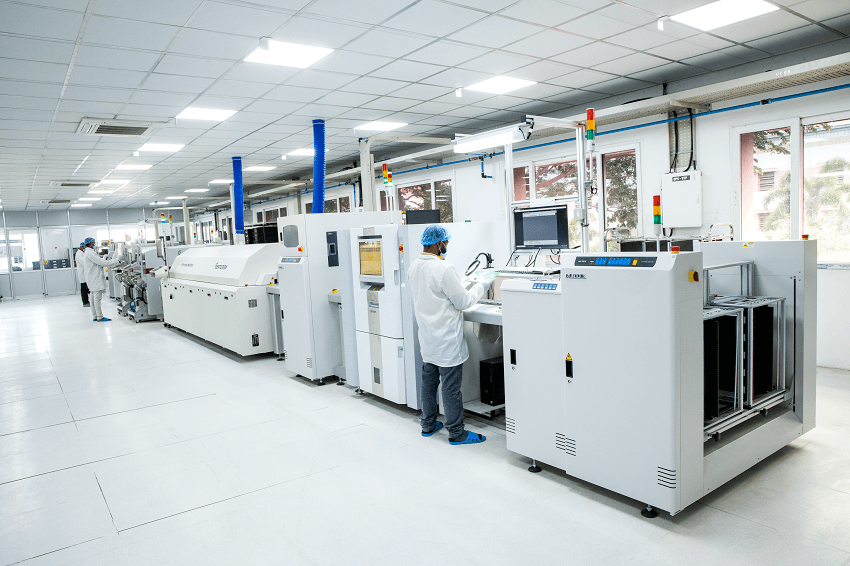

- Automated optical inspection

- In-circuit test

- X-ray inspection

- Full functional testing, automatic testing equipment and End of Line (EOL) testing

- Conformal coating

- IPC 610 standards class 2 and class 3

- Design for manufacturing (DFM), Design for Assembly (DFA) & Design for Test (DFT) analysis

- End to End manufacturing traceability

- Rapid prototyping

What types of PCB assembly services do you provide?

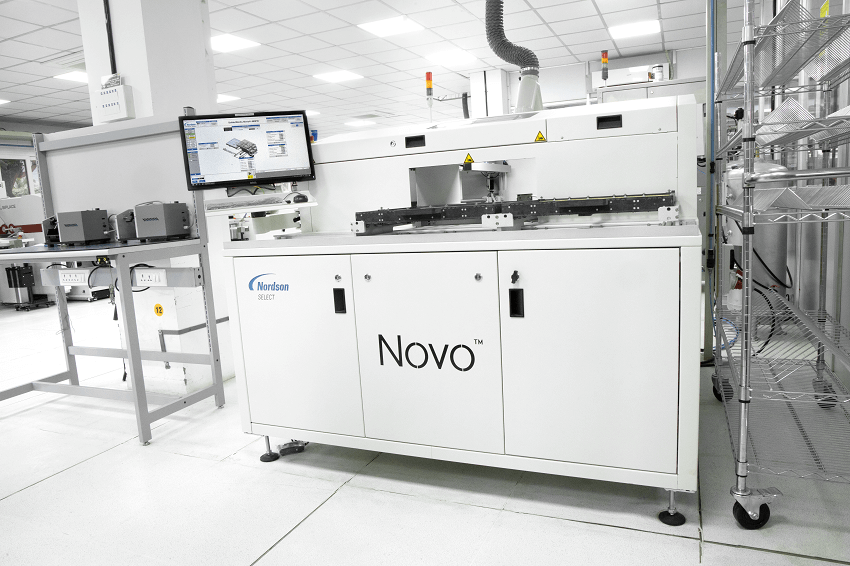

We offer comprehensive assembly services including SMT, Through-Hole, Selective Soldering, Manual Soldering, and BGA Rework.

Do you support both leaded and lead-free (RoHS compliant) assembly?

We strictly adhere to RoHS compliance and support only lead-free PCB assembly.

What file formats do you require for PCB assembly?

We require Gerber, DWG, BOM, Pick & Place, and testing files to ensure seamless assembly.

Do you offer both prototype and volume production assembly?

Yes, we cater to both prototype runs and high-volume production requirements.

What is the minimum and maximum order quantity you can handle?

We handle orders starting from 150 units with no upper limit on quantity.

Do you perform quality testing like AOI, X-ray, or functional testing?

Yes, our quality assurance includes AOI, In-Circuit, Functional, End-of-Line, Endurance, Flashing, Custom Product Validation, and X-ray testing.

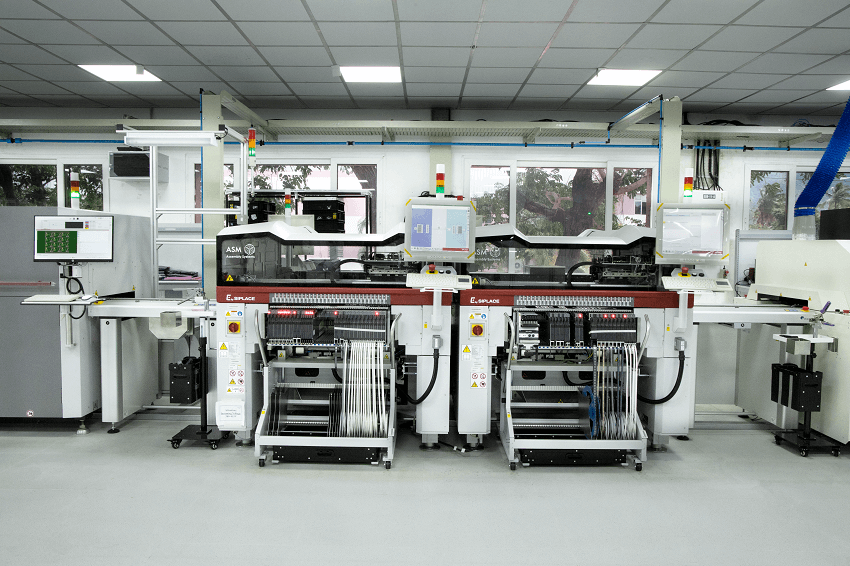

What technologies do you use in your SMT line?

Our SMT line is powered by advanced ASM software technology to ensure precision and efficiency.

Our Major Services are:

- Electronic Design, PCB Assemblies, Products and Systems Integration Services

- Prototyping, Sourcing, Turnkey Manufacturing and Support Services of High Mix , Medium Volume Assemblies

- Design and Development of Embedded Products/Systems

- Roots incorporate all life cycle service capabilities, qualifications, and certifications required by the Industry including design verification, validation service, conducting ESS & Durability tests as per MIL Standards Surface Mount Technology (SMT), Through Hole Technology (THT), Mixed Technology (SMT, THT),Vapor Phase Soldering, Lead-Free (RoHS), No Clean Fluxes, Single and Double-Sided Component Placement, Conformal Coating, Laser Marking.

Roots is a recognized leader in Automotive Components and our SMT production develops solutions for our customers using the latest in PCB assembly and surface mount technology. Capabilities include support for:

- 01005 components placement capable, fine pitch and high count BGAs, Maximum Components height is 19mm, Two Stage Placement Head Speed at 69500CPH.

- Inspection and testing using the latest SPI(Solder Paste Inspection), AOI(Automated Optical Inspection), X-ray Inspection, ICT(In Circuit Test), FT(Functional Test), BIT(Burn in Test)

Roots committed to provide high-end technological solutions to our clients globally. It’s helped us to become a world provider of unbeatable production and assembly. We meet the sector specifications of our clients, whether they require an immediate turnaround prototype or large-scale production PCB assembly, with IPC Standards certified professional. We build everything from towering count and flattering back panels & box build assembly to designs that include buried, we can provide an extensive range of products to our customers with the fastest delivery times.